Our Factories

Potato Chips Factory

Corn Snacks Factory

Biscuits Factory

El Alameya

Potato Chips Factory

Feeding our communities with passion and hard work, Senyorita dedicates its factories for the production of the highest quality foods and snacks. Since the establishment of our Leader factory in the city of Mahala – Gharbeya governorate we have created a partnership of excellence with our surrounding community. Opening up new horizons for industry we began our production with less than 100 employees and have grown our human resources today to employ more than 560 Egyptians mostly from our home city.

To ensure that our factories receive the best supply of clean and nutritional products, we work with our suppliers to encourage farmers and growers of potatoes (our main raw material) to utilize the highest standards of agricultural practices. Guiding the growers for best practices as well as for planting the best species in terms of yield and quality products we have developed a strong community bond based on trust and the transfer of knowledge and information. Our production process begins by selecting only the best quality potatoes for our chips by a team of highly trained of experts.

Through a fully automated process our keenly selected potatoes are passed on to a rigorous cleansing stage and then prepared for processing in our state of the art production line. Utilizing the most advanced Japanese production lines we process thousands of cartons of freshly prepared chips per day. Raising the bar for quality and performance we introduced the most sophisticated systems to our factory in 2012 making it the most advanced of its kind in the region.

The production process is carefully monitored with constant testing and follow up procedures to ensure the manufacturing of the highest quality products for our consumers. Our quality assurance labs and testing stations cover the strictest international standards for chemical and microbiology requirements. We screen our products at every stage with top of the line lab equipment and the latest technological tools that are operated by a team of the finest technicians and scientists in the business.

Our process continues with the most up to date packaging and packing systems that can tend to the most detailed customer requirements. Throughout our production process we deliver a variety of brands and flavors for our local & export markets. Once our finished products are packaged and sorted they are transferred to our warehouses, where we maintain the strictest codes for storage and handling.

We have earned local, regional and international recognition and respect for our products and services catering for a diverse set of clients with ever growing orders and requirements which we fulfill through a dedicated team of market and administrative professionals. The Leader facility provides its products to over eleven countries in Africa and Asia and continually seeks to expand its customer destination list with a wide variety of quality products that cater to all needs.

×

Corn Snacks Factory:

The Market Experts of Extruded Snacks and Products

Ranked as number one in the business, Senyorita has been producing extruded corn products for over quarter of a century. Sourcing the finest corn grits at our oldest and biggest facility in Tanta city – Gharbeya governorate, we produce a vast variety of flavors and snacks which makes us the authority on corn snacks in the MENA region. Since our facilities were established in the early 90’s we have utilized the finest machinery, techniques and recipes feeding our customers with tasty and scrumptious snacks.

Our production process begins far away from our facilities, where our suppliers work tirelessly to select and procure the best quality corn for our products. Our precious raw material is stored in the state of the art silos and specialized warehouses awaiting orders for production. Graded, evaluated and tested for quality and content the corn batches are then introduced into our production process for thorough cleaning and screening. Incorporating the latest technologies from the USA, Japan, France and Italy, our production lines are the finest and most up to date in the business. Cooked with our secret recipe the corn grit is transformed into our highly successful brands of Windows, Chicka, Ahlawy and Break with over eleven flavors combined.

Throughout every step of the way from raw material to finished products we are constantly testing samples at our labs. Americana’s code of excellence is implemented via the highest levels of quality assurance methodologies and verification processes.

Spread over 40,000 m2 (almost 10 acres) our production plant is a unique juggernaut of its kind. The entire facility is monitored via closed circuit cameras. With its own water and waste water treatment plants, a web of asphalt paved roads; we have enabled our facilities with the most advanced network of infrastructure.

Although our facility is fully automated our staff numbers have grown in direct proportion to the immense growth in production and the need to handle an average between 130 – 150 tons of raw material every day. Operating this vast plant, our workforce has multiplied from 50 workers in 1992 to over 1500 talented professionals today. Our human resources play a great part in our infamous tale of success. We nurture excellence by combining talent with training, encouragement, motivation and care.

×

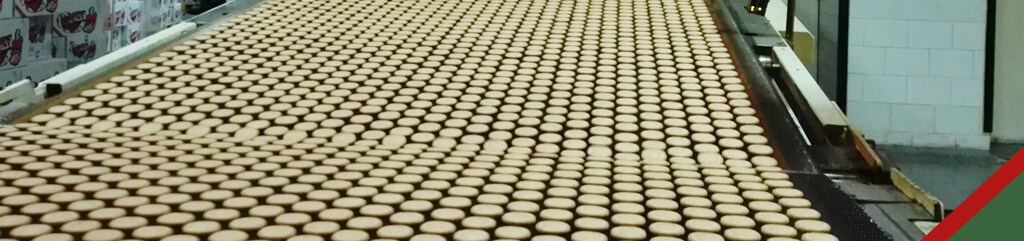

Biscuits Factory:

A Story of Sweet Success

For over three decades we have mastered the art of producing the finest biscuits and sweets. Set in the ancient city of Alexandria, our oldest production facility is one of the most advanced in the world. Utilizing Dutch technology, we produce the finest, freshest and tastiest biscuits for our customers.

Although we were established in 1983, we began the actual production of biscuits in 1985 with one line. Producing an average of 600 cartons-3Tons per day we had less than 50 employees. Gaining a new momentum from the Americana management we were encouraged to expand. Inspired by the vision for achieving excellence the May Egypt crew were able to implement local modifications to the production line multiplying the output by more than 600% in 2012.

The markets could not get enough of our specialty biscuits compelling us to undertake a bigger expansion in 2015 almost doubling our production capacity.

May Egypt’s facility is spread over an area of 8480 m2 that is neatly designed for optimal operations. Our unique infrastructure network seves the production facility built on three floors with an average area of 1600m2 per floor. The whole premises is monitored via ccc and our facility is fitted with the top of the line emergency alarms and systems.

As production grew, Americana's unwavering drive for excellence was a key element for our continuous success. Utilizing its international experience May Egypt demands the best supplies and ingredients for the production lines. Our suppliers provide us with the best wheat, sugar, shortening and flavors that enable us to bake our biscuits to perfection.

Our standard of excellence is applied at all times, from the supply of raw materials and the rigorous testing process to the storage facilities that are monitored closely to the preparation process then on to our ovens to the packaging. We repeatedly conduct thorough random tests ensuring the freshness, tastiness and finesse of our biscuits.

×

El Alameya:

Our Pride and Joy

The latest addition to our Americana family is our futuristic facility in Sadat city – Monufeya Governorate. The city is named after one of Egypt's most popular and respected leaders, former presidents Anwar El Sadat. Building on this sentiment we have created a facility worthy of pride and respect for our community and our customers throughout the region. Equipped with the most advanced production lines this facility is unmatched in its ability to satisfy quality and quantity.

Surrounded by an agricultural community, El Alameya was designed to achieve multiple objectives. Primarily the facility would include a specialized plant to freeze and store fresh produce from the fields. Additionally it would include a new biscuit production line that was procured in 2008. Later in 2009 the facility grew to include a special production line for corrugated card board boxes dedicated to supply our production lines everywhere.

To serve the three functions, El Alameya maintains one of the most sophisticated infrastructure systems in Egypt. Equipped with the finest standards of health, safety and environmental safeguards, the facility is self-sustainable in the areas of water treatment, waste water treatment, solid waste management air quality monitoring systems. The premises is also connected by a fully paved roads network that serves all the sectors of the facility.

At this facility we produce delicious sweets and munchies for an ever growing audience. Starting with a small production capacity of 870 cartons – 4.350 Tons per day. In 2012 we introduced a new line to increase the production output of our biscuits. With ever growing demand for our product we upgraded our capabilities in 2014 raising our speed and packing. In Feb 2015 we purchased a new line specialized in producing our wonderful wafers. In April 2015 we operated our latest production line for sandwich biscuits.

×